Firestop meets UK and EU fire safety standards and advice on application may be given to meet building regulations."

Steel – Interior and Exterior

Top Firestop Intumescent paint for steel, structural steel and cast iron will always provide in excess of 120-minute fire protection and are provided in a range of colours for both interior and exterior use. Our fire-resistant paints are easy to apply by brush, roller or spray, with no specialist skills required and fire certificate issued on completion.

Please contact us about obtaining a certificate of conformity with your purchase, how to calculate how much intumescent paint you may need for a project or surface/substrate m2 area – meeting the specification required by building regulations – how much protection can be obtained with listed coatings, what the differences are between Class 0 and Class 1 fire protection, and more.

Important fire test standards when using intumescent coatings on structural steel constructions are European Union: EN 13381-8 (Replaces national Standards in Europe) and United Kingdom: BS 476-20/21 (Commonly referred to in EU, Middle and Far East).

Wood – Interior and Exterior

Top Firestop Intumescent paint for wood is a new generation of fire retardant maintenance paint that can be used as part of a flame and fire retardant system for timber surfaces. As part of a complete system it controls surface spread of flame and fire propagation, total smoke control, flaming droplets and particulates to BS EN Class B s1 d0.

When applied as instructed it meets new Fire Regulations standard BS EN Class B s1 d0 and complies with British Standard Class 1 and Class 0 Surface Spread of Flame. For 30 & 60 minutes Fire Resistance. It actually exceeds 120 mins.

When exposed to fire:-

- Smoke and flame retardant Top Top Fire Stop suppresses toxic gasses & prevents

- Top Firestop expands to create a barrier, insulating wood from heat and oxygen to prevent wood burning & fire penetration

Prepare & apply according to manufacturer’s instructions

- Pressure Pot & Gun conventional unit with small compressor

- Ensure all traces of solvent flushed out

- Thin 5 > 10% with water to spray viscosity

- Adjust fluid flow & air flow as normal for acrylic emulsion paint

OR

- Airless Graco 1500, 3500 or equivalent

- 3/8” line, 30 mesh filter on machine, not filter in gun

- 521 or 523, broad areas 621 or 623 tip

Ensure coverage is applied as per can – i.e. 20m² can covers 20m², 80m² can covers 80m², etc. Never add water or other mixing solvents to Top Firestop

Plaster Board

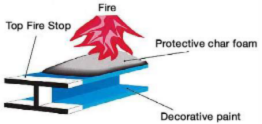

When flames come into contact with Top Fire Stop, the paint in that area starts to transform into a char which acts like an insulating carbonising foam and it expands. This char does not allow the flames to penetrate the layer of the paint, thus the don’t reach the substrate surface underneath it. It stops the spreading of fire as the char does not burn. The increased volume and decreased density slow down the heating of the surface below the paint. The thicker the layer of paint the more char and consequently the more protection it will provide.

A minimum thin layer of 0.1 – 0.5mm is sufficient for a good level of fire protection. Minimum two coats of paint, one vertical and one horizontal.

Top Fire Stop intumescent paint was specifically designed to be applied

on any construction surface types and materials such as wooden surfaces,

complex metallic structures, spray polyurethane foam ,thermal insulation .plasterboards etc,

indoor and outdoor, for residential, commercial and industrial buildings.

Coating just touched by flame

Flame touch time extends, temperature about 250oC

Flame touch time furtherly extends, temperature about 250oC

Flame touch time extends, temperature about 650oC